Table of contents

ToggleEngine power has been a major preoccupation of motorsport fans for a long time. Indeed, discussions between enthusiasts of motorcycles, cars or other vehicles often focus, unsurprisingly, on power. But how does one go about measuring power? The “seat of the pants” ? Not quite, for while this is ultimately where we feel its effects, it has proven to be a rather imprecise device to be sure. Ah, but there is a device that can accurately measure power and it is known as a dynamometer. Commonly known as a “dyno,” it’s a tool that can measure the torque and power of an engine package.

Power: From Watt to today

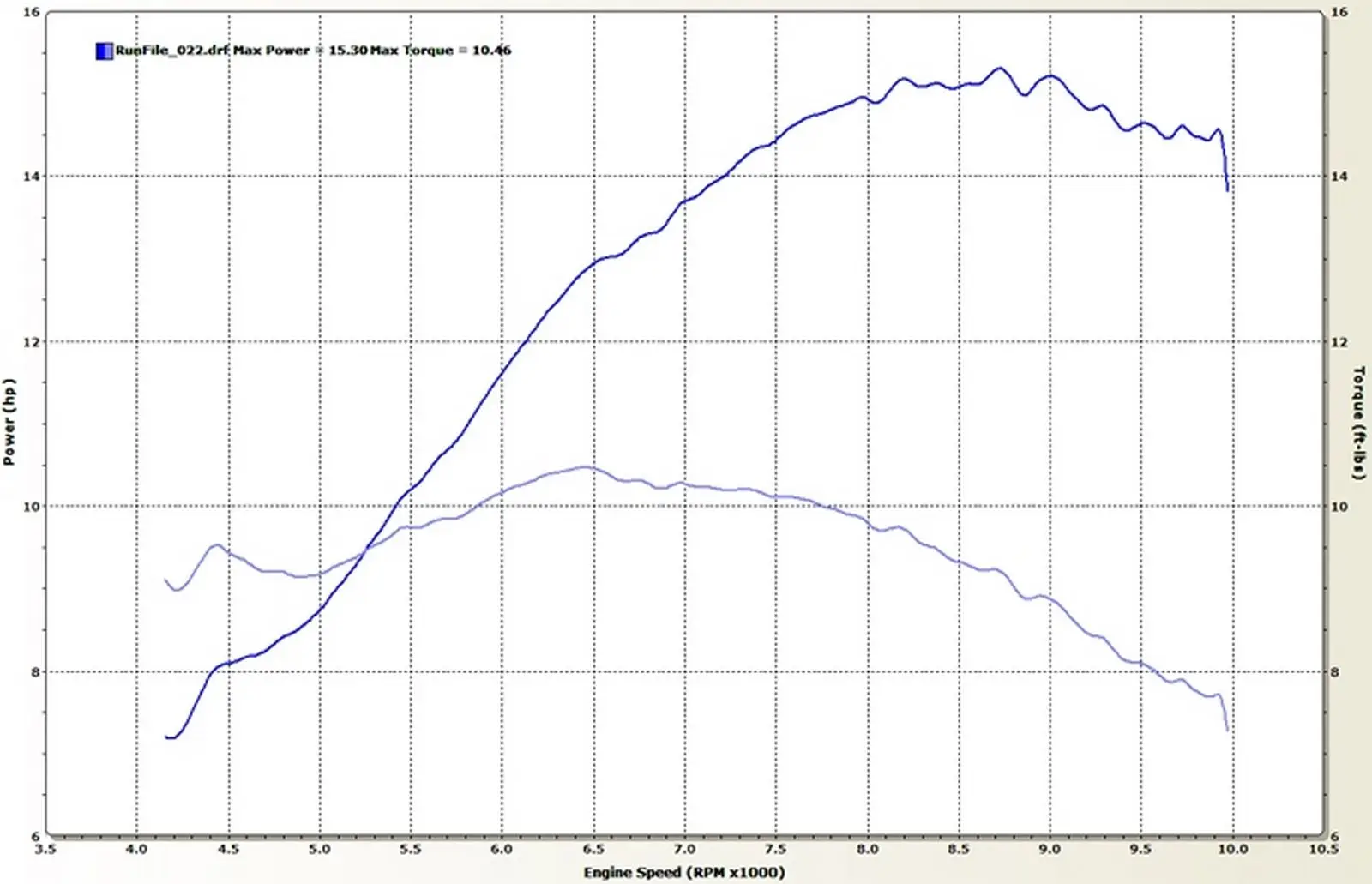

Horsepower is a measure of an engine’s ability to do work (within a certain amount of time). It is dependent on two elements: force (torque) and speed. For more details on engine power, you can read my article on the subject here. In truth, there is no way to directly measure an engine’s power. However, all is not lost as we have the means to measure the two aforementioned critical elements, allowing us to arrive at it indirectly by simple math.

The Origins of Horsepower

Various units exist for measuring power, the most common of them (at least in North America) being horsepower. British engineer James Watt was the first to coin this measure unit at the beginning of the Industrial Revolution. Originally, it was defined as the ability to lift a 33,000 lb load on a distance of 1 ft in one minute. In other words, it represented the approximate work capacity of a horse. Things have evolved since and an equivalent formula has been developed. This modern method is, quite obviously, simpler to use than Watt’s.

Power (hp) = torque (lb-ft) x speed (rpm)

5,252

Notice how the formula includes the two factors mentioned previously (i.e., torque and speed).

An Eternal Question: Metric or Imperial?

Other units of measure for power include the Watt (W), or kiloWatt (kW), and the metric horsepower (mhp). The latter can sometimes lead to confusion, especially when the “m” is omitted. For the record, 1 mhp is equal to 98.6% of an imperial hp. In other words, 100 mhp is equal to 98.6 hp. It is worth noting, somewhat unsurprisingly, that European manufacturers have a tendency to use the metric unit, which tends to inflate their claimed power numbers slightly.

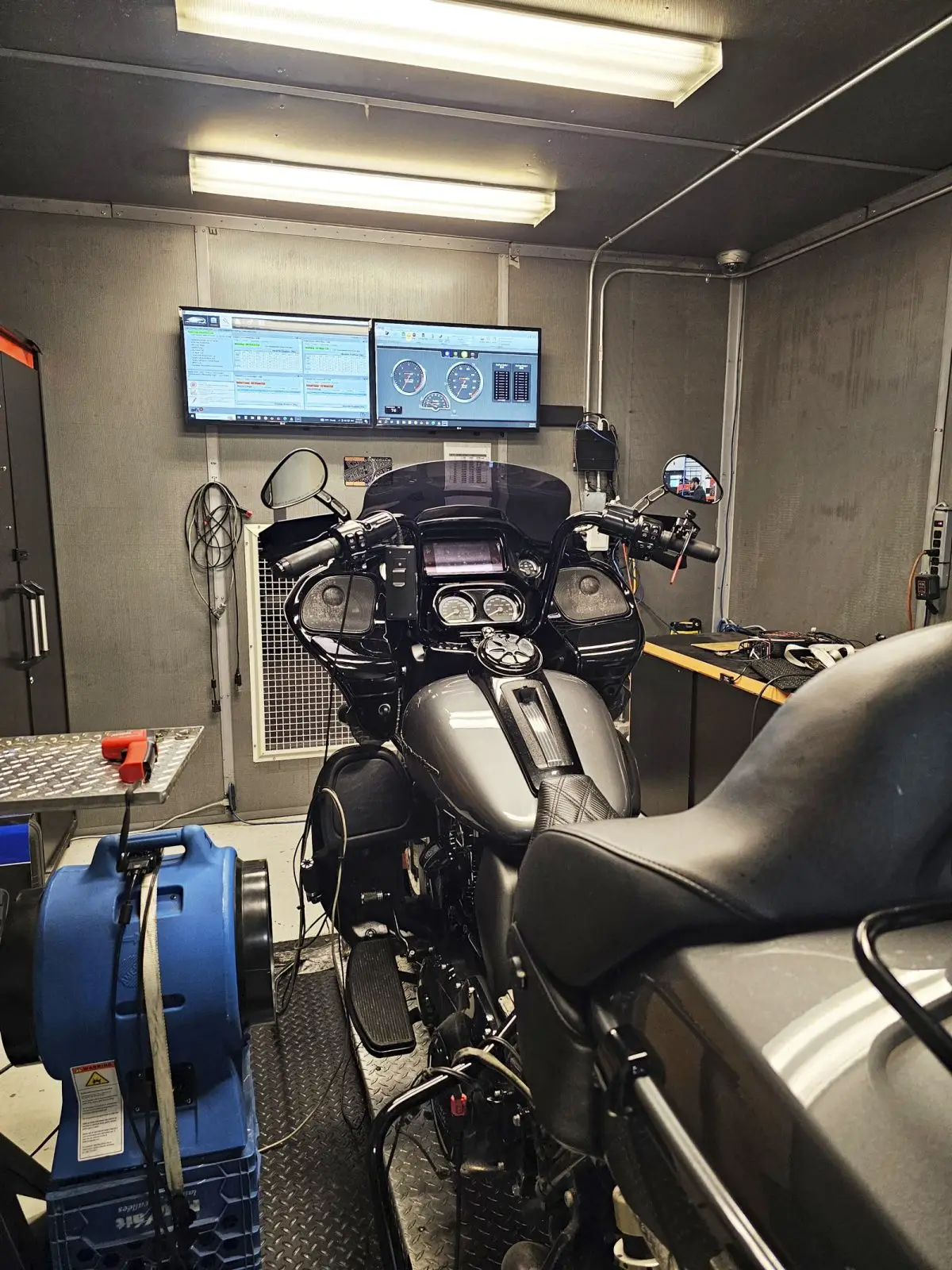

The dynamometer at work

Different types of dynamometers

The dynamometer is a device, a tool, that we hook up to the engine, either directly or indirectly, that allows us to measure engine torque and speed. As demonstrated previously, with this data in hand, we can then calculate engine power. Different types of dynos exist but these generally fall into one of two categories: inertia or brake type.

Inertia Dyno

In the case of inertia dynos (by far the most common type used in the motorcycle industry), the dynamometer requires that the engine (or the rear wheel to be precise) spins a heavy drum, torque being calculated from the latter’s acceleration.

Brake Dyno

In the case of the brake dyno, the unit applies resistance to the engine (i.e. “braking” it) and torque is calculated from the amount of effort required to slow down the engine. Assorted braking systems are used, one of which is a water recirculation configuration, consisting of fluid being pumped through some piping (this particular type of unit is very popular in the snowmobile industry, for example). As the engine runs, an adjustable valve is slowly closed to restrict the movement of the fluid while the power is calculated by measuring the flow volume, fluid pressure, and engine speed. Another type from this family is the “Eddy current” dyno, which operates on the premise of forcing a conductive material to rotate through an electromagnetic field, the reverse force created by the resulting Eddy current acting to resist engine torque.

Complex Formulas for Precise Results

In all instances, computers use complex formulas to calculate torque across the engine’s operating speed range. This information is then combined with engine speed data to calculate engine power.

It goes without saying that power readings obtained directly at the engine’s crankshaft are superior to those measured at the rear wheel, namely because crankshaft numbers are not compromised by drivetrain friction and slippage.